Manchester is renowned for its illustrious industrial past. It was the birthplace of the Industrial Revolution in the late 18th and early 19th centuries. Its humid climate, proximity to rivers, and strategic location made Manchester the ideal centre for the growth of the textile industry, as reported by manchestername.com.

The city eagerly adopted all technological innovations of the time, often leading the way in their implementation. This article explores how Manchester embraced coal as a key resource for its industrial growth.

Dependence on Rivers

Engines to perform various tasks had existed for a long time. The critical question was their source of power. Early engines relied on hydropower, which came with a major limitation—they had to be situated near rivers, streams, or waterways.

While this posed no significant issue for grain or oil mills, which naturally needed to be near processing facilities, it was a problem for the textile industry due to the limited availability of riverside locations.

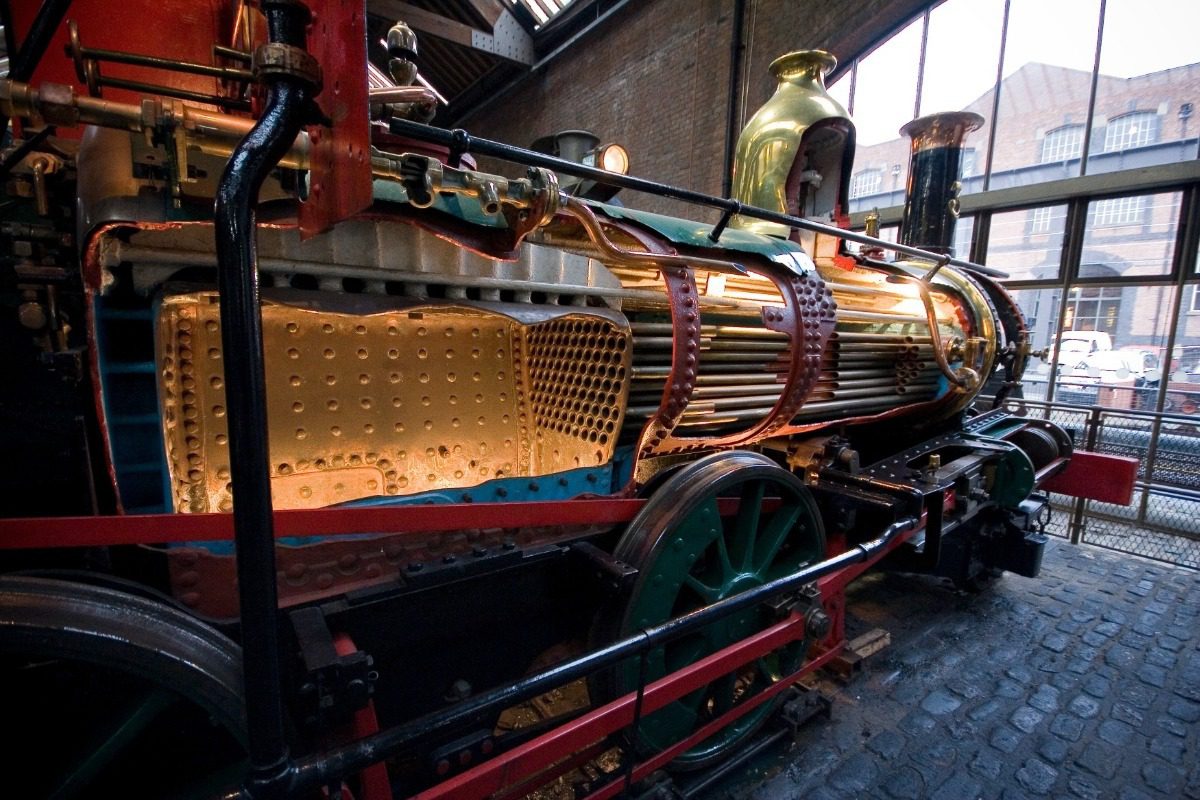

In 1712, Thomas Newcomen invented the world’s first steam engine. Though it was large, expensive, and inefficient by modern standards, it was the first device capable of generating mechanical energy by burning coal. Due to its high coal consumption, Newcomen’s steam engine was primarily used in coal mining operations.

The true beginning of the Industrial Revolution came with James Watt’s groundbreaking innovation in 1778. Watt significantly improved the steam engine, increasing its efficiency fivefold. His steam engine was revolutionary in that it could power mill wheels and factory machinery.

The Emergence of Coal-Powered Steam Engines

By the early 19th century, coal burning had become the primary energy source for Manchester’s industry. Fortunately, coal was relatively inexpensive to procure, as the nearby Lancashire coalfields had been mined since medieval times. However, it was during the Industrial Revolution that coal production expanded significantly.

With the introduction of coal-powered steam engines, the need to build factories near rivers diminished. Textile mills and factories began sprouting up across Manchester. The combination of Watt’s steam engine and increased imports of cotton from American plantations transformed Manchester into a thriving hub of factories and mills.

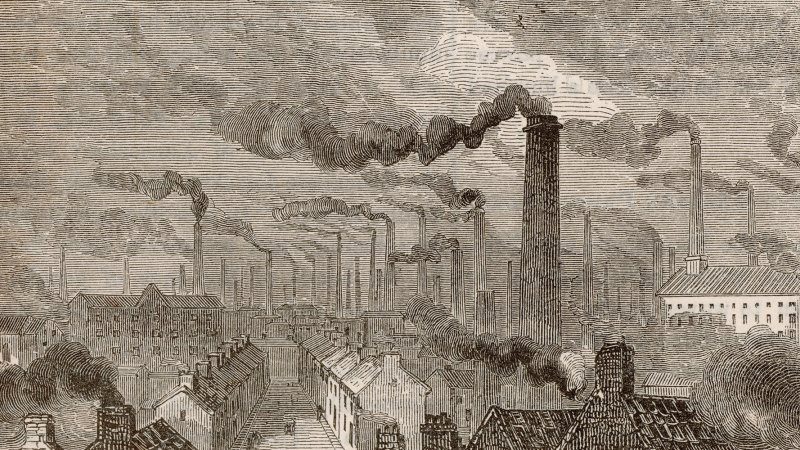

Coal became ubiquitous in Manchester. Residents used coal-fired stoves to heat their homes and cook meals. Over time, more advanced and efficient engines emerged, producing greater energy output per ton of coal. Across the city, an increasing number of chimneys released plumes of black smoke.

The Consequences of Coal Dependency

Manchester’s shift to coal combustion brought with it a host of negative consequences. Burning coal released carbon dioxide and ash, which heavily polluted the city. At the height of the Industrial Revolution, residents endured thick black smoke that obscured the sun even on clear days. Smog frequently enveloped the city, while soot and ash blanketed roads and buildings.

These conditions significantly impacted public health. Respiratory illnesses were common, and areas with the highest industrial activity saw elevated mortality rates.

Concerned citizens formed Smoke Abatement Societies, advocating for technological solutions such as more efficient steam boilers and a transition to gas. They also called for stricter legislation to protect the city from excessive smoke emissions. However, progress was slow, and the implementation of such measures lagged behind the urgency of the problem.